Here we demonstrate an effect which looks like the classic

tractor beam seen in science fiction films and tv shows. We have made pieces of

thin graphene which can levitate over a bed of rare earth permanent magnets can

be ‘pushed’ around or made to spin using a handheld, focusable 5mW 390-405nm laser

beam.

The phenomenon demonstrates visibly how it is possible to

convert light, either from a laser beam or focused sunlight, to mechanical

energy.

This demonstrates simple principles of transferring energy,

as well as how motors and engines can operate on the principle of the magnetic

spin degrees of freedom to create reversible heat cycles where no atoms or

molecules are moved, offering a possible alternative way to harness solar

energy.

It also demonstrates the principles of a maglev, how in

certain materials diamagnetism can be used to levitate objects off a track of

magnets.

Considering that this principle works at room temperature,

unlike current high temperature superconductors, it could be useful as an easy demonstration

kit in schools as no cooling liquid, such as liquid nitrogen, is needed.

By depositing ferromagnetic nanoparticles on the graphene

thin films it was also found that the films could bend in exposure to the UV

light and return to their original position when the exposure stopped,

demonstrating a weak hysteresis in the material for potential use as a optical

memory material.

The fact that a low-powered laser can move the grapheme from

a reasonable distance in a vacuum could mean it could become a practical tool

for movement of thin films of grapheme for manufacturing purposes in the not

too distant future should graphene become useful in industrial and consumer

electronics, perhaps eventually moving to replace silicon as a transistor material in the not too distant future.

Although the band gap in graphene cannot be controlled as

easily as it can be in silicon, hence the universality of silicon in transistor

and memory technology, researchers are working on ways to create a stable

bandgap in graphene via doping and structuring of deformations in thin films of

the material.

Due to the thin nature of the films, robotic tweezers used for

holding silicon wafers are relativtive clumsy devices for holding thin films.

Hence, using lasers to transport the films at least on assembly lines fitted

with magnets could be an attractive way to avoid damaging fragile circuitry

etched on the graphene paper. Other functions, such as frictionless motors

guided by lasers, may also be applicable from this technology.

Nature

of Magnetism

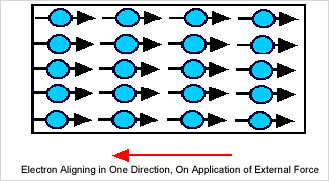

Magnetism is the direct result of electron spin, which can

be imagined as a distinct directional arrow attached to each particle. In

magnetic materials, when all of these individual arrows point in the same

direction they produce the cumulative effect of a magnetic field – e.g, the

north/south orientation of magnets.

Down on the nanometer scale, at billionths of a meter,

electron spins rapidly communicate with each other. When a spin flips inside a

magnet, this disturbance can propagate through the material as a wave, tipping

the neighboring spins in its path.

This coherent spin wave, called a magnon by the convention introduced in 1930 by Felix Bloch, is theorised to be what creates the magnetic transport properties in high-temperature superconductivity.T hermal excitations of magnons also affects the specific heats and saturation magnetisation of ferromagnetism, leading to the famous specific heat formula derived by Bloch

In the case of the thermally excited magnons, the Bose-Einstein energy distribution, U, is valid for a magnon of frequency ω :

Where the integral in is taken over the 1st Brillouin Zone.

In the limit of low temperatures, for the density of states:

The flux of magnons are particularly strong in high temperature superconducting materials, so strong in fact that they reject external magnetic fields entirely, creating the Meissner effect which expels the magnet from the superconductor causing the magnet to levitate above the superconductor once the material has been lowered below a critical temperature Tc.

This coherent spin wave, called a magnon by the convention introduced in 1930 by Felix Bloch, is theorised to be what creates the magnetic transport properties in high-temperature superconductivity.T hermal excitations of magnons also affects the specific heats and saturation magnetisation of ferromagnetism, leading to the famous specific heat formula derived by Bloch

In the case of the thermally excited magnons, the Bose-Einstein energy distribution, U, is valid for a magnon of frequency ω :

Where the integral in is taken over the 1st Brillouin Zone.

In the limit of low temperatures, for the density of states:

The resulting specific heat of the magnons is then found to be:

Energy spectra of magnons in superconductors for example is determined by inelastic neutron scattering experiments. The specific heat of magnons as derived by Bloch in also contribute to the heat conductivity in certain materials, in particular diamonds and have contributions in other carbon atom crystal structures too such as graphene.

The flux of magnons are particularly strong in high temperature superconducting materials, so strong in fact that they reject external magnetic fields entirely, creating the Meissner effect which expels the magnet from the superconductor causing the magnet to levitate above the superconductor once the material has been lowered below a critical temperature Tc.

Developments in superconducting materials technology have

produced superconductors which can enter the superconducting phase above the

boiling point of liquid nitrogen allowing for table top demonstrations of the

Meissner effect.

When the temperature

of the superconducting material is above the critical temperature, the magnetic

field penetrates the superconductor freely. When it is lowered below the

critical temperature, the magnetic field is rejected from entering the

superconductor causing the magnet to levitate above it.

Diamagnetism

Diamagnetism is defined by the generation of a spontaneous

magnetization of a material which

A diamagnetic substance is one whose atoms have no permanent

magnetic dipole moment, so the spins of the outer electrons are in a

inhomogeneous state. When the orbital motion of electrons of any atom changes it results in diamagnetism.

When an external magnetic field is applied to a diamagnetic substance,(such as water, bismuth, ect), a weak magnetic dipole moment is induced in the direction opposite to the the applied field. This is known as Lenz’ Law in electromagnetism.

In quantum mechanics, the magnetic dipole moment is oriented in the direction of the spin angular momentum of the electrons, hence a change in the magnetic dipole moment experienced by them changes the spin orientation of the electrons to oppose the field in quantised units, represented by arrows, to oppose the external field in the same proportion.

Classically, we can say diamagnetism is the speeding up or slowing down of electrons in their atomic orbits and this results from the changing of the magnetic moment of the orbital in a direction opposing the external field. From any interpretation of the physics, diamagnetic materials repels the external magnetic field.

In the following order of diamagnetic constant, here are a few significant diamagnetic elements from the periodic table.

When an external magnetic field is applied to a diamagnetic substance,(such as water, bismuth, ect), a weak magnetic dipole moment is induced in the direction opposite to the the applied field. This is known as Lenz’ Law in electromagnetism.

In quantum mechanics, the magnetic dipole moment is oriented in the direction of the spin angular momentum of the electrons, hence a change in the magnetic dipole moment experienced by them changes the spin orientation of the electrons to oppose the field in quantised units, represented by arrows, to oppose the external field in the same proportion.

Classically, we can say diamagnetism is the speeding up or slowing down of electrons in their atomic orbits and this results from the changing of the magnetic moment of the orbital in a direction opposing the external field. From any interpretation of the physics, diamagnetic materials repels the external magnetic field.

In the following order of diamagnetic constant, here are a few significant diamagnetic elements from the periodic table.

• Bismuth

• Mercury

• Silver

• Carbon

(Graphite, Graphene, Carbon Nanotubes, Fullerenes, ect)

• Lead

• Copper

All materials are somewhat diamagnetic, in that a weak

repulsive force is generated by in a magnetic field by the current of the

orbiting electron. This causes the

electrons to not uniformly align by themselves and instead form small domains,

where only a few electrons have their spins aligned in a particular

direction. This repulsive force is

overcome by the strength of the external field. In this case, all of the electrons in the

material will align uniformly in the direction of the applied field lines. This

is known as ferromagnetism.

Other materials, however, have stronger repulsive qualities

that overcome their natural diamagnetic qualities. Hence, domains do not form in these materials

and the spin directions are truly random. In the presence of an external field,

the electrons which will try to spin in opposite directions,

Some Ferromagnetic Elements

• Iron

• Nickel

• Cobalt

• Gadolinium

• Dysprosium

Some Paramagnetic Elements

• Uranium

• Platinum

• Aluminum

• Sodium

• Oxygen

Diamagnetic Levitation occurs by bringing a diamagnetic

material in close proximity to material that produces a magnetic field. The diamagnetic material will repel the

material producing the magnetic field.

Generally, however, this repulsive force is not strong enough to

overcome the force of gravity on the Earth's surface. To cause diamagnetic levitation, both the

diamagnetic material and magnetic material must produce a combined repulsive

force to overcome the force of gravity.

There are a number of ways to achieve this:

Placing Diamagnetic

Material in Strong Electromagnetic Fields

Modern Electromagnets are capable of producing extremely

strong magnetic fields. These

electromagnets have been used to levitate many diamagnetic materials including

weakly diamagnetic materials such as organic matter.

A popular educational demonstration involves the placement

of small frogs into a strong static electromagnetic field. The frog, being composed of primarily water,

acts as a weak diamagnet and is levitated.

This procedure is completely safe for the frog as the

magnetic field is nowhere near strong enough to affect the chemical or

electrical processes in complex organic life, with spiders and mice having no signs

of illness or injury. With a large enough electromagnet even a human could be

levitated, in principle.

Placing Magnetic Material in Strong Diamagnetic Fields

In the case of the superconducting maglev the diamagnetism is induced by

superconductivity in the ceramic material. Superconductors in the Meissner

state exhibit perfect diamagnetism, or superdiamagnetism, meaning that the

total magnetic field is very close to zero deep inside them (many penetration

depths from the surface). This means that the magnetic susceptibility of a superconductor is negative

The fundamental origins of diamagnetism in superconductors

and normal materials are very different. In normal materials diamagnetism

arises as a direct result of the orbital spin of electrons about the nuclei of

an atom induced electromagnetically by the application of an applied field. In superconductors

the perfect diamagnetism arises from persistent screening currents which flow

to oppose the applied field (the Meissner effect); not solely the orbital spin.

Placing Diamagnetic

Material in Strong Magnetic Fields

Advancements in the development of permanent magnets and

diamagnetic materials such as pyrolytic graphite have produced a simple method

of diamagnetic levitation by simply placing a thin piece of pyrolytic graphite

over a strong rare-earth magnet. The pyrolytic graphite is levitated above the

magnet.

Placing Magnetic

Material in Diamagnetic Fields with a Biasing Magnet

The last method, and most easily duplicated by the average

individual, uses a combination of readily available rare-earth magnets and

diamagnetic material such as carbon graphite or bismuth. Through the use of a biasing or compensating

magnet, a small rare-earth magnet can be levitated above a piece of diamagnetic

material. For added stability, the small

magnet is generally placed between two pieces of diamagnetic material. Below is a diagram of this method:

All of these demonstration apparatus have been, more or

less, mainstream in their incorporation into various niche areas. The study of

how to manipulate these effects into technology which has easy to replicate applications

is sometimes hard to do as it requires sensitive equipment and the payoff may

not be obvious. Superconductivity, for example, when first discovered was hard to achieve and as such it was hard to incorporate outside of a very narrow field of study and application. We are only seeing how much potential the field has today and even so it is only the tip of the iceberg.

In studying these effects and using existing

technology we have set up a demonstration of how some of the physics behind

these stationary demonstrations can create a dynamic device which could be useful

for some applications in microelectronics assembly and miniature robotics to

name a few areas. In it, we combine lasers, magnetism and graphene making it a useful

gadget in explaining some physics on the side of a weird toy if nothing else!

Reversible

Heat Cycles in Graphene – Levitating Laser Driven Motion Devices.

In 1984, the famous American Physicist Richard Feynman gave

a talk called “Tiny Machines”. This was to be a follow up of a previous talk he

gave in 1954 at Caltech on Nanotechnology titled “There’s Plenty of Room at the

Bottom”. Since many advances in microscopic manufacture had been released

between 1954 and 1984, Feynman felt that he could give even more insight. In

this talk he mentioned, in a brief question and answer session, that the

internal mechanism of heat transfer in an internal combustion engine on the

nanoscale of atoms could be accomplished using reversible cycles of quantum

spin.

“All concept of heat in heat cycles depends on random motion

of particles being transferred, however it does not have to be the motion of

atoms or molecules vibrating like in a classical, combustion heat engine but it

could be the heat of quantum spin, that is the magnetisation directions of the

atoms are swishing up and down although the atoms and molecules themselves are

remaining in place, offering a different scale at which we can get heat

operating systems and reversible cycles.” – Richard Feynman, 1984.

Here, using graphene thin films in diamagnetic levitation,

we have developed, what is in effect, the magnetic-based reversible engine that Feynman had alluded

to being possible back in the 1980’s.

Graphene, like its parent compound Graphite, is a strongly

diamagnetic material, so it can be levitated in the ~1.2 Tesla magnetic fields

of permanent NdFeB magnets, rather than superconducting electromagnets.

Graphene is an excellent conductor of heat and electricity.

Hence any small changes in temperature or electronic interactions in one region

will quickly dissipate to the rest of the material.

Graphene therefore has excellent photothermal properties, so

that even a weak light source , such as a focused laser, can heat up the

graphene film in one region instantly, which affects its magnetic

susceptibility, making it tilt and hence move.

The fact that graphene also releases heat rapidly allows the

process to be instantly reversible, which is what allows the film to move so

responsively. Hence, the graphene film does not simply collapse onto the magnet

as it loses its magnetic susceptibility, it simply tilts in one region and

stays levitating on the region opposite from the laser focus as the heat dissipates

before it reaches there.

The sum of the forces, ∑F(B) , exerted from the magnetic dipoles, ∑m1, on our magnetic chessboard grid on another sum of dipoles in our levitating film, ∑m2, separated in space by a vector r can be calculated using

Where is the ΦB external magnetic field of each dipole magnet in the chessboard grid.

Our sheet, which has a real mass, M0 , in zero field, is levitating with an effective mass M0 in a balance of magnetic, ΦB, and gravitation fields, ΦG.

So the sum of gravitational forces ∑F(G) and the magnetic forces ∑F(B) are therefore balanced:

So every time we change the dipole moment of the levitating film, m2 , we change the effective mass, M2, of the levitating film in the field balance.

We do so by heating it with a light source, in our case a focused 405nm 5mW laser.

The local heating induced by the laser sets off a chain reaction of magnetic dipole reversal in the diamagnetic material, which in a quantum mechanics viewpoint, we can represent as a sum of uniform units of spin angular momentum pointed in the direction opposite to the externally applied magnetic force.

The chain reaction should therefore propagate itself by exchanging momentum between the neighbouring dipole moments in a gated but entirely stochastic (i.e. random) fashion in a similar way to how a wildfires spreads

The local heating induced by the laser sets off a chain

reaction of magnetic domain reversal, in a similar way to how runaway chemical

or physical reactions or even how forest wildfires spread. The magnetic domain

reversal changes the diamagnetic constant in the region, hence lowering the

levitating film slightly in the direction of the directed beam.

Due to the lowered magnetic susceptibility in the heated region, this region is not contributing to the levitation however the mass is still distributed the same. The overall magnetic dipole reversal therefore increases the overall effective mass in the region heated, hence lowering the levitating film slightly in the direction of the directed beam.

Due to the lowered magnetic susceptibility in the heated region, this region is not contributing to the levitation however the mass is still distributed the same. The overall magnetic dipole reversal therefore increases the overall effective mass in the region heated, hence lowering the levitating film slightly in the direction of the directed beam.

We

can think of this like a lever where the side that is lowered is now considered

to be the “load” the

entire film is bearing.

Since the film is levitating in free space above the

magnets, the fulcrum is in the centre of gravity of the film. In this

case the work

is applied on the side of the fulcrum opposite to the load applied and the

resistance son the other side. Hence the direction the film is pushed is

towards the load by the force of

gravity.

As the graphene “lever” rotates around the fulcrum, the points

farther from the fulcrum move faster than points closer to the fulcrum.

Therefore a force applied to a point farther from the fulcrum must be less than

the force located at a point closer in, because power is the product of force

and velocity. Hence by directing the beam toward the edge of the film, we

create the load at the edge, which in turn means the force is delivered at the

opposite edge and this causes the points to rotate much faster around the

fulcrum hence moving the film rapidly.

The responsivity and reversibility of the cycle induced comes

from the fact that the levitating diamagnetic graphene film, in the presence of

the 1.2 Tesla magnetic, has a metastable magnetic susceptibility. In other

words, the direction of the electron spin in the matieral is in a metastable

state within the external magnetic field. This makes sense, energetically, as the

levitating graphene film is in a higher energy state than the non-levitating

film. Hence, when heat energy is delivered to a magnetic domain, at threshold energy,

it then flips from a higher-energy metastable state to a lower-energy stable

state, from which energy is released as heat. If enough energy is released, the

temperature of the surrounding domains will rise to the point that they also

flip, releasing more heat. This can spark a chain reaction that rapidly causes

the magnetization of the entire region affected to reverse direction.

So the energy released when a spin changes its spin orientation

depends on the external magnetic field. If the field is weak, the energy is

small and the heat simply dissipates. In this case, the spins reverse gradually

by thermal diffusion, typically over a period of a few milliseconds, as the

heat from the applied heat pulse thermally diffuses along the crystal structure.

Above a critical magnetic field, however,

the energy released by one spin flipping provides enough activation energy to

flip adjacent spins. In this case, a wave of spin flips will propagate through

a magnetic domain in the material at a constant speed, reversing all the spins much

faster than thermal effects can take action, about 1000 times faster than

thermal diffusion, such that the magnetic susceptibility can be changed

significantly in the heating region.

The reversibility of the cycle also comes from the fact that

the movement of spin waves is severely limited at room temperature, and thermal

effects will quickly overwhelm the spin wave with interference away from the

heat source. Hence, the heat will dissipate quickly away from the region

heated, making the whole cycle reversible.

Applications beyond demonstration.

As with any technology, the applications are only limited by

the constraints of physics, engineering and our own necessity and imagination.

Already I can think of uses in contactless assembly manufacturing

of graphene circuits from reduced graphene oxide on an assembly line

configuration. Laser scribing of graphene oxide to graphene has of course huge

potential in the microelectronics industry over the next decade and beyond. This can be done with both UV and IR Laser Etchers.

Graphene Circuits, etched by Infrared Laser on Graphene Oxide paper

In the following video, we reduce Graphene Oxide (GO) to Graphene in an interdigitated circuit pattern using a home-built robotic UV laser etching machine.

Perhaps, using a weak UV “Tractor Beam” laser, it might be possible to have contactless assembly line of graphene circuit manufacture.

The delicacy of such films, along with how graphene produced from reduced graphene oxide is vulnerable to defects, could be a main application for which these devices could be designed for, aside from their use in demonstrations.

As shown in Atomic Force Microscope scans of graphene grown from reduced graphene oxide, there is a huge amount of defects. Hence, for small scale manufacture, a way to move the substrate around without damaging it may be crucial.

(A) Contact-mode AFM scan of reduced graphene oxide etched on a graphene oxide paper substrate

(B) Height profile through the dashed line shown in part A.

(C) Histogram of platelet thicknesses from images of 140 platelets. The mean thickness is

1.75 nm.

(D) Histogram of diameters from the same 140 platelets.

Perhaps, using a weak UV “Tractor Beam” laser, it might be possible to have contactless assembly line of graphene circuit manufacture.

The delicacy of such films, along with how graphene produced from reduced graphene oxide is vulnerable to defects, could be a main application for which these devices could be designed for, aside from their use in demonstrations.

As shown in Atomic Force Microscope scans of graphene grown from reduced graphene oxide, there is a huge amount of defects. Hence, for small scale manufacture, a way to move the substrate around without damaging it may be crucial.

(A) Contact-mode AFM scan of reduced graphene oxide etched on a graphene oxide paper substrate

(B) Height profile through the dashed line shown in part A.

(C) Histogram of platelet thicknesses from images of 140 platelets. The mean thickness is

1.75 nm.

(D) Histogram of diameters from the same 140 platelets.

Although other techniques for growing graphene exist, growing graphene by reducing graphene oxide is the most efficient method and currently the easiest. Hence developing new manufacturing technologies for optimizing its production is well worth doing.

In other experiments, levitating micro-sized graphene wheels on circular rare-earth magnets have been driven to speeds of about 200 rpm with UV lasers.

Just like in the force-load-fulcrum explanation of operation the wheels move based on the analogous torque-load-axis, hence the laser directed at one end of the wheel will create a torque of motion at the opposite end towards the strain induced by the load created as the laser lowers the magnetic susceptibility on one side.

The torque exerted by one magnetic dipole moment m1 on another m2 separated in space by a vector r can be calculated using the equation of torque under a field:

Hence the laser directed at one end of the wheel will create a torque of motion at the opposite end towards the strain induced by the load created as the laser lowers the magnetic susceptibility on one side

This may be of importance in the field of nanorobotics.

Another application which could be combined with this technology is using laser operated tweezers based on graphene oxide films coated with ferromagnetic nanoparticles which, under application of a laser, can create a phase change in the magnetization of the particles by lowering the magnetic susceptibility of some of the particles to the point at which the direction of magnetization becomes disordered (at the Curie point) in the particles exposed to the laser.

Ferromagnetic nanoparticles consist of intrinsic magnetic moments which are separated into domains called Weiss domains. This can result in some nanostructured ferromagnetic materials having no spontaneous magnetism as domains can be engineered to potentially balance each other out.

The position of nanoparticles can therefore have different orientations around the surface than the main part (bulk) of the material. This property directly affects the Curie Temperature as there can be a bulk Curie Temperature TB and a different surface Curie Temperature TS for a material.

The change in magnetic field orientation of the nanoparticle coating in turn causes the magnetic dipoles in the graphene oxide molecules to change shape slightly, making the crystal lattice longer in one dimension and shorter in other dimensions, hence creating a stress in the material and inducing a change in shape. This process is reversible, and as such has a hysteresis. Hence this allows the material to have a shape-memory.

This may eventually allow for a new scale at which motorized systems can be pushed to work at. Lack of electrical components would also mean liquids provide no damage to the function aside from increased turbulence which would require a more powerful laser to work against.

Bilayer paper-like materials based on graphene-based platelets and ferromagnetic nanoparticles can also be engineered to strongly deform in response to other force-bearing stimuli such as differentials in temperature.

Light-responsive graphene oxide (GO) + ferromagnetic nanoparticle composite fibres fibers can be prepared by the positioned laser deposition of ferromagnetic magnetite (Fe3O4) nanoparticles onto a GO substrate.

The ferromagnetic nanoparticle layer is about 10 µm thick.

Magnetite nanoparticles, on the order of 1 and 100 nanometers, are important for research in superparamagnetic systems, at which the nanoparticles have very large magnetic susceptibilities which allow for fast manipulation of the magnetization of the system, which can occur using light absorption.

When exposed to UV laser light, the asymmetric (Fe3O4) /(GO) fibers display complex, well-controlled motion/deformation in a predetermined manner.

The bilayer material also has other interesting physical properties. For example, the surface of the graphene oxide layer is magnetically conducting but electrically insulating while the surface of the ferromagnetic nanoparticle layer is electrically and magnetically conducting. This electrical asymmetry could come in handy for applications.

For this more research is needed for how the actuators deform under certain stimuli. Also on the to do list: study curling response times and how stable the devices are.

Another application which could be combined with this technology is using laser operated tweezers based on graphene oxide films coated with ferromagnetic nanoparticles which, under application of a laser, can create a phase change in the magnetization of the particles by lowering the magnetic susceptibility of some of the particles to the point at which the direction of magnetization becomes disordered (at the Curie point) in the particles exposed to the laser.

The Curie Point refers to a characteristic point at which a material is at the boundary of having its magnetic dipole moments as being in the ferromangetic regime.

In Ferromagnetic materials, the magnetic moments are aligned at random at temperatures above the Curie point, where the magnetic suceptability is lowered. and become ordered at temperatures below the Curie Point, where magnetic susceptability is highered.

As the temperature is increased towards the Curie point, the alignment (magnetization) within each domain decreases. Above the Curie point, the material is purely paramagnetic and there are no magnetized domains of aligned moments

Ferromagnetic nanoparticles consist of intrinsic magnetic moments which are separated into domains called Weiss domains. This can result in some nanostructured ferromagnetic materials having no spontaneous magnetism as domains can be engineered to potentially balance each other out.

The position of nanoparticles can therefore have different orientations around the surface than the main part (bulk) of the material. This property directly affects the Curie Temperature as there can be a bulk Curie Temperature TB and a different surface Curie Temperature TS for a material.

This allows for the surface Curie Temperature to be ferromagnetic above the bulk Curie Temperature when the main state is disordered, i.e. Ordered and disordered states occur simultaneously.

The change in magnetic field orientation of the nanoparticle coating in turn causes the magnetic dipoles in the graphene oxide molecules to change shape slightly, making the crystal lattice longer in one dimension and shorter in other dimensions, hence creating a stress in the material and inducing a change in shape. This process is reversible, and as such has a hysteresis. Hence this allows the material to have a shape-memory.

This may eventually allow for a new scale at which motorized systems can be pushed to work at. Lack of electrical components would also mean liquids provide no damage to the function aside from increased turbulence which would require a more powerful laser to work against.

Bilayer paper-like materials based on graphene-based platelets and ferromagnetic nanoparticles can also be engineered to strongly deform in response to other force-bearing stimuli such as differentials in temperature.

Light-responsive graphene oxide (GO) + ferromagnetic nanoparticle composite fibres fibers can be prepared by the positioned laser deposition of ferromagnetic magnetite (Fe3O4) nanoparticles onto a GO substrate.

The ferromagnetic nanoparticle layer is about 10 µm thick.

Magnetite nanoparticles, on the order of 1 and 100 nanometers, are important for research in superparamagnetic systems, at which the nanoparticles have very large magnetic susceptibilities which allow for fast manipulation of the magnetization of the system, which can occur using light absorption.

When exposed to UV laser light, the asymmetric (Fe3O4) /(GO) fibers display complex, well-controlled motion/deformation in a predetermined manner.

The bilayer material also has other interesting physical properties. For example, the surface of the graphene oxide layer is magnetically conducting but electrically insulating while the surface of the ferromagnetic nanoparticle layer is electrically and magnetically conducting. This electrical asymmetry could come in handy for applications.

For this more research is needed for how the actuators deform under certain stimuli. Also on the to do list: study curling response times and how stable the devices are.

These fibers can function not only as a single-fiber flexing actuator under UV laser alternation but also as a new platform for micromechanical systems, (MEMS), Nanomechanical systems (NEMS) optoelectronics, smart textiles, ect.

All in all, these gadgets are fun to design and build and along with it having applications for a science demonstration it may also be a welcome tool for contactless graphene manufacture, which I will hope to demonstrate

online shortly using laser scribing of graphene.

Over the coming weeks and months I will hope to put up a few

more design specifications, matlab simulations and other things so that if

anyone wants to replicate this device themselves (maybe even doing it cheaper

which would be impressive!). I will also be planning, very soon, to sell, for the moment at

least, ten of these in small version kits (more if people are interested). Each one cost around $70 to build, for

the rare earth magnet tiles, focusable laser and about 4 pieces of graphene

paper thrown in. The large kit would obviously be more expensive, due to the

sheer number of magnets, and was designed for manufacturing and positioning

of the films and testing them with various lasers for etching circuits.

If there is a significant interest from people wanting to buy these I will make more. An added bonus of this would be that as they are bought, the price will go down in the manufacture as the demand would be, as the economists say, a financial security in and of itself. If there is no real interest then I will just update the blog with the specifications and that will be that.

If there is a significant interest from people wanting to buy these I will make more. An added bonus of this would be that as they are bought, the price will go down in the manufacture as the demand would be, as the economists say, a financial security in and of itself. If there is no real interest then I will just update the blog with the specifications and that will be that.

Further Reading (for the Biophysics and Medically inclined):

03/08/12 - Magnetic Levitation Detects Proteins, Could Diagnose Disease

magnetic levitation could also find use in diagnosing disease. Researchers at Harvard have shown that they can detect proteins in blood using MagLev.

magnetic levitation could also find use in diagnosing disease. Researchers at Harvard have shown that they can detect proteins in blood using MagLev.

magnetic levitation could also find use in diagnosing disease. Researchers at Harvard have shown that they can detect proteins in blood using MagLev.

magnetic levitation could also find use in diagnosing disease. Researchers at Harvard have shown that they can detect proteins in blood using MagLev.

The researchers, led by George Whitesides, use levitation to detect a change in the density of porous gel beads that occurs when a protein binds to ligands inside the beads.

The lower the bead levitates, the more protein it holds. The method could work for detecting disease proteins in people's blood samples in the developing world: The magnets cost only about $5 each, and the device requires no electricity or batteries.

Because the beads are visible to the naked eye, researchers can make measurements with a simple ruler with a millimeter scale."

To analyze the interactions of a protein, bovine carbonic anhydrase, with small-molecule inhibitors, he and his colleagues attached the inhibitors to the inside surfaces of colored diamagnetic beads, with a different color for each of the five molecules. They added the beads to a cuvette containing the protein in a paramagnetic gadolinium(III)-containing buffer, and allowed the protein to diffuse into the beads over several days.

The researchers placed the cuvette between two magnets oriented with their north poles facing each other at the top and bottom of the cuvette. Three forces acted on the beads. The magnets pushed the beads from the bottom of the cuvette. Meanwhile, the gadolinium ions moved toward – and displaced the beads away from -- the magnets. And, finally, gravity pulled the beads downward. These three forces balanced out so that the beads levitated at a height determined by their density. Because high-affinity inhibitors bound more protein, their beads had higher densities and levitated lower. By measuring the distance from the bottom of the cuvette to the beads, the researchers could calculate the binding affinities of the inhibitors.

The researchers realized that their method could also measure concentrations of a protein in a sample if they measured the height of beads coated with a single high-affinity inhibitor. As a proof-of-principle experiment for disease protein detection, the investigators used this method to measure concentrations of a protein added to blood samples.

The main advantages of the levitation system are its low cost and portability. Rare-earth magnets cost only about $5 each, and the process required no electricity or batteries. Because the beads are visible to the naked eye, researchers can make measurements with a simple ruler with a millimeter scale and it would not be difficult to perform such measurements automatically with a computer. Moreover, with the increasing demand for lab-on-a-chip devices with biological fluid and particle scanning capability for versatile medical scanners, the applications of science like this could be very useful indeed for medical diagnostic technology.

.gif)

No comments:

Post a Comment

Note: only a member of this blog may post a comment.